XPE - a new building material for heat preservation, heat insulation and water resistance | PAIDU

In the construction industry, the use of EPE for waterproofing has become the norm. However, due to its lack of performance, this material often leaks in a short time and other problems, which has brought great troubles to the construction. In addition, due to the complex construction process of EPE and frequent replacement, the use and production costs have also increased significantly.

In this context, XPE becomes the best alternative to EPE. In some national key projects, XPE has been adopted as a waterproof material. For example, the Three Gorges Project, the South-to-North Water Diversion project, the Beijing subway and other large projects have used XPE as a waterproof material.

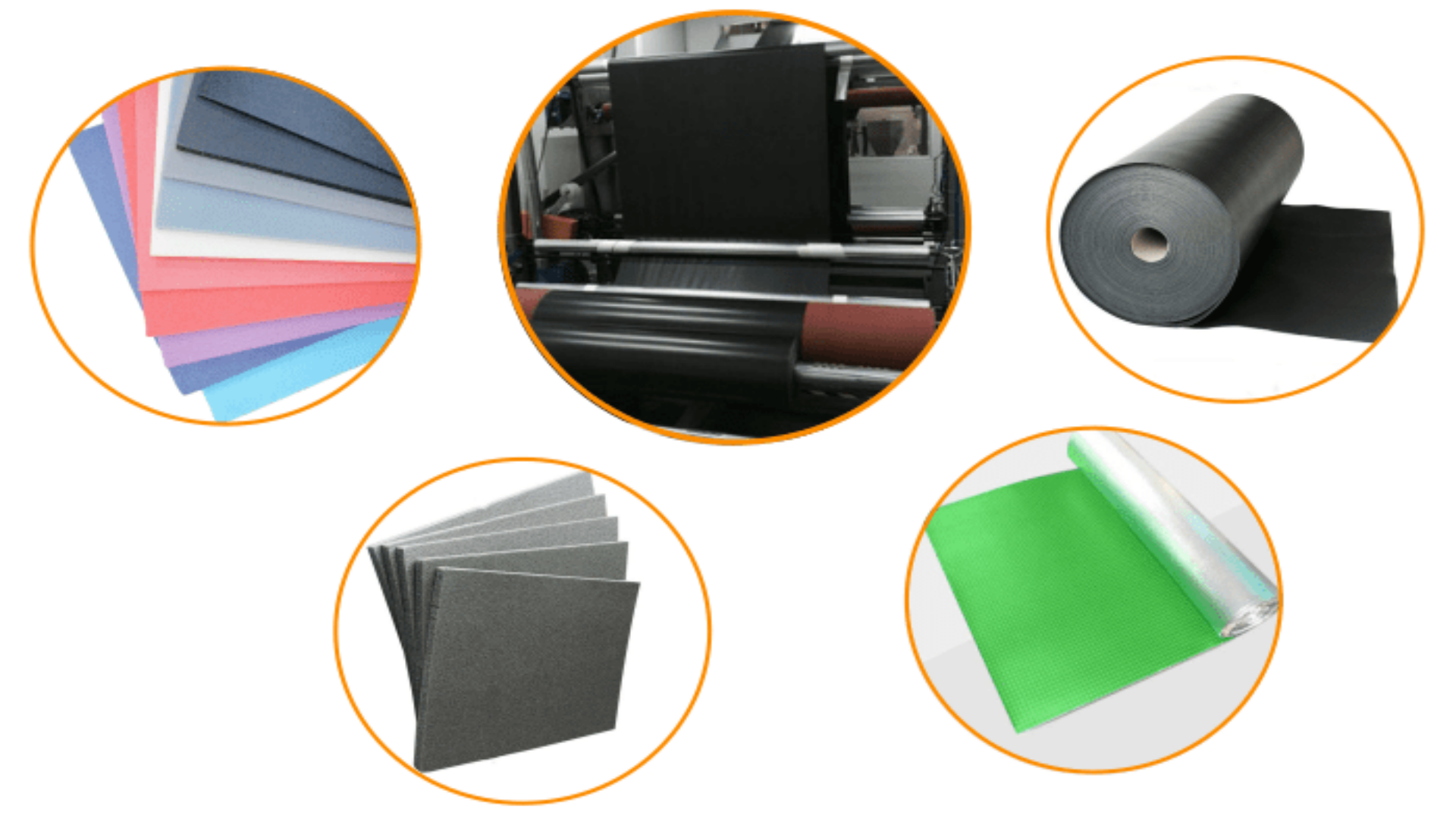

XPE foam sheet not only has excellent thermal insulation performance, but also has waterproof and moisture-proof, soft and light weight, low temperature resistance, anti-aging and other characteristics. Developed countries have been using XPE for insulation in house construction and air-conditioning projects since the beginning of this century. This material not only solves the discomfort brought by glass fiber and foam materials to the human body and the harm to the environment, but also through the composite aluminum foil on the surface of the polyethylene material, so that it has good insulation, light and heat reflection, anti-radiation and other functions.

In the field of construction and civil engineering, XPE foam sheets can be used as roof, wall insulation, heat preservation, buffering, anti-condensation, waterproof, leak-proof and anti-corrosion materials. It can also be used for civil construction of various basic materials, anti-freeze, anti-shock buffer materials, as well as interior decoration, wallpaper, mattress materials and so on. In addition, XPE can also be used as a soundproofing material for floors and multi-storey buildings, a sealing filler material for the joints of subway tunnels, lightweight structures of house walls and doors and Windows, a joint material for filling two uneven surfaces, a covering material for promoting cement curing and preventing heat and moisture loss, and a thermal insulation material for central air conditioning pipe networks. It is worth mentioning that the internal pore structure of XPE foam sheet is uniform and closed, which can play a buffer, shock absorption and impact resistance effect. In order to further improve its performance, a woven cloth can also be compounded on the surface of XPE to improve its tensile and tear strength.

In recent years, with the continuous improvement of people's awareness of environmental protection, XPE foam material, as an environmentally friendly material, has received more and more attention and application. Its production process does not produce harmful substances, can be completely recycled and reused, in line with the requirements of sustainable development.

Although there are still some difficulties to overcome in the promotion and application of XPE foam sheet, its excellent performance and environmental protection advantages make it an important development direction for the future construction industry. With the continuous progress of technology and the improvement of people's environmental protection requirements, we believe that XPE foam materials will be widely used in more fields, bringing more benefits to our lives and the environment. With the increasing demand for comfort and energy saving, the application of XPE foam sheet in the construction field in China has gradually received widespread attention. This material has become an integral part of modern buildings due to its excellent thermal, sound and moisture insulation properties. With the progress of science and technology and the improvement of environmental awareness, it is believed that the demand for XPE foam materials in China will grow rapidly.