Unlocking the Potential of IXPE Foam: Transforming Solutions for PAIDU

What is IXPE Foam?

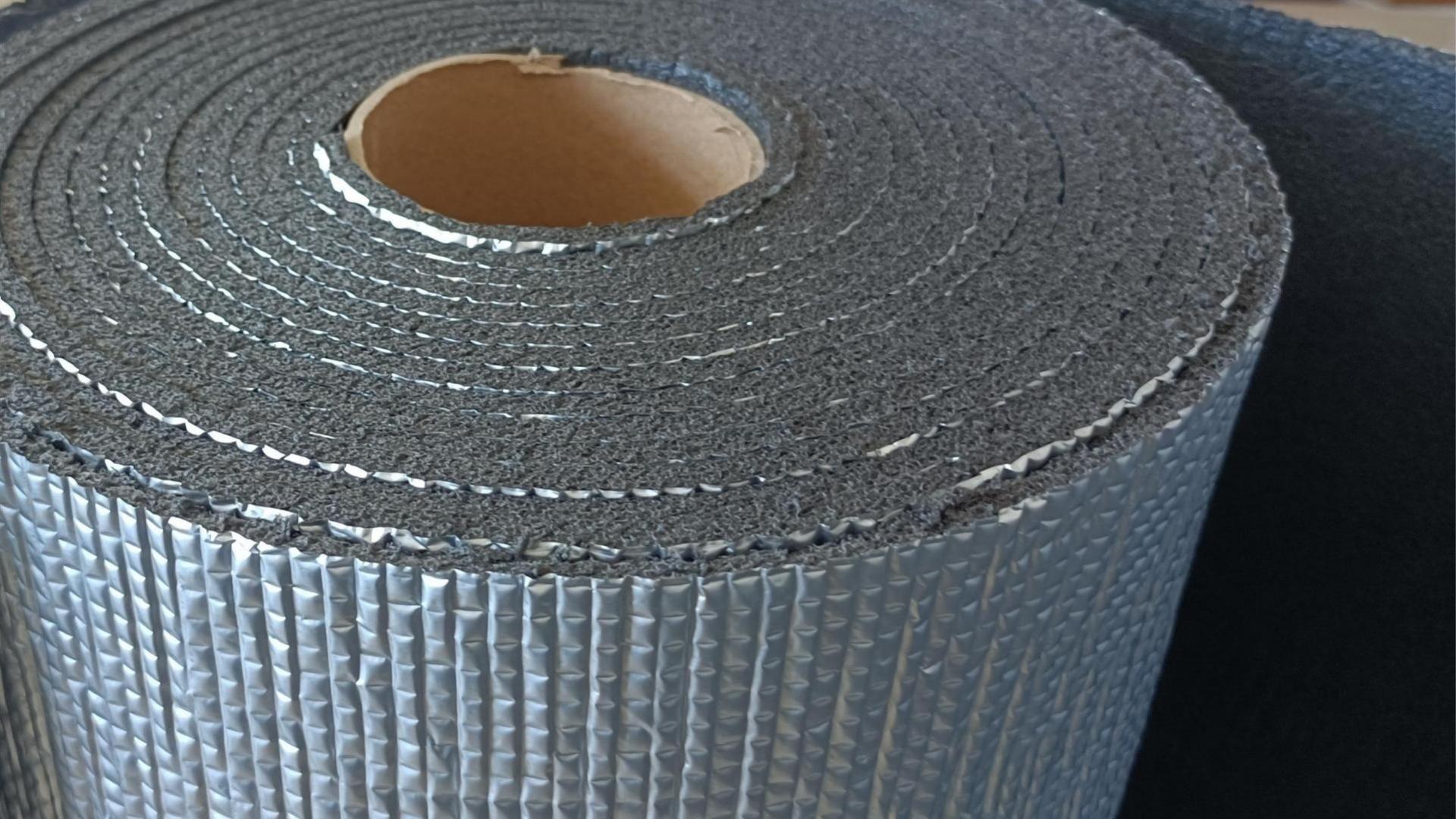

IXPE foam is a closed-cell foam that is produced through a cross-linking process, resulting in a lightweight, durable material with several advantageous properties. Its unique structure provides exceptional thermal insulation, buoyancy, and moisture resistance, making it suitable for a wide range of applications across various sectors.

Key Benefits of IXPE Foam

1. Durability and Resilience: One of the most attractive qualities of IXPE foam is its resistance to wear and tear. This makes it an ideal choice for products that experience high levels of usage and require long-lasting performance.

2. Thermal Insulation: IXPE foam’s excellent insulation capabilities make it a popular choice for applications that require temperature control. It can effectively reduce heat transfer, which is crucial for packaging sensitive items and maintaining the quality of temperature-sensitive materials.

3. Water and Moisture Resistance: The closed-cell structure of IXPE foam prevents water absorption, ensuring that products remain lightweight and resistant to damage from moisture. This makes it particularly useful in industries like construction and packaging.

4. Lightweight and Buoyant: The low density of IXPE foam allows for easy handling and transportation. Its buoyant properties also make it valuable in marine applications, where it can be used in navigation aids and floating devices.

5. Eco-Friendly: As sustainability becomes a priority for businesses and consumers alike, IXPE foam emerges as a viable option. It is recyclable and can help companies reduce their environmental impact while still delivering high-quality products.

Applications of IXPE Foam

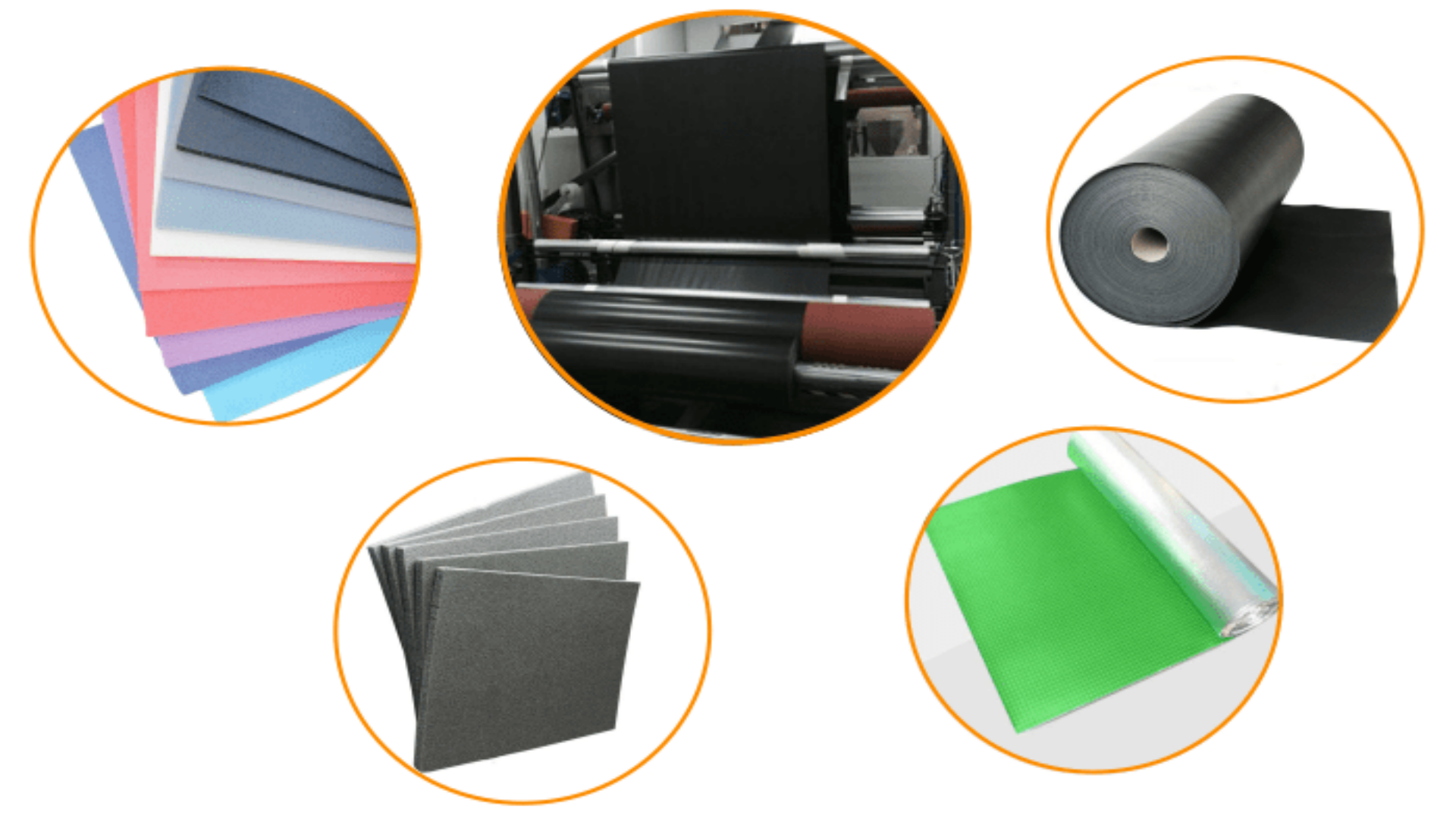

The versatility of IXPE foam opens the door to numerous applications across multiple industries:

Packaging: IXPE foam provides superior cushioning, making it ideal for packaging fragile items. The foam’s durability ensures that products remain safe during transportation.

Construction: Used in insulation panels, IXPE foam enhances energy efficiency in buildings by reducing thermal loss, contributing to sustainable construction practices.

Automotive: In the automotive industry, IXPE foam serves as an effective material for sound and vibration dampening, leading to quieter interiors and improved ride comfort.

Sports: IXPE foam is commonly used in sports equipment for impact absorption, providing athletes with the protection they need without compromising performance.

Medical Devices: Thanks to its cushioning properties, IXPE foam is used in medical devices to enhance patient comfort and protect sensitive equipment.

Conclusion

For PAIDU, integrating IXPE foam into your product lines could lead to significant benefits, including enhanced durability, improved insulation, and greater customer satisfaction. As an eco-friendly and adaptable material, IXPE foam has the potential to support innovative solutions tailored to your market needs.

By embracing IXPE foam, PAIDU can not only stay ahead of industry trends but also offer customers a product that exemplifies quality and sustainability. The future of your product offerings could be revolutionized by harnessing the capabilities of this remarkable material.